Gallery

The finished product

Our projects are artistic, mechanical, monochromatic, brightly colored, industrial, and visual. Simply put – they are as unique as our clients. The projects that allow us to bring your creation to life, is what we thrive on!

Range Hood - Copper Commercial

Back to GalleryYear Completed

2018Cost for something similar

5200.00Project Description

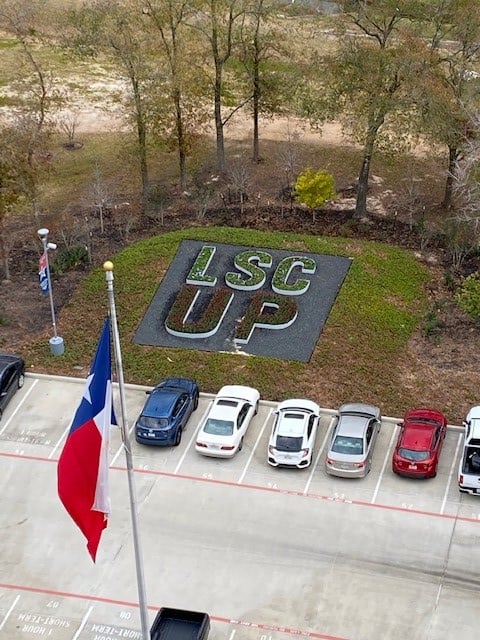

Planters - Lone Star College

Back to GalleryYear Completed

2019Cost for something similar

14000.00Project Description

These planters are located on the University Park Campus of Lone Star College and are constructed out of steal.

Escalantes - Hanging Bar Shelf & Wine Rack

Back to GalleryProject Description

Fountain at Hotel Zaza

Back to GalleryProject Description

Fountain runnel designed and fabricated for the Memorial City Hotel Zaza. Constructed out of Stainless Steal

Flower Ring exposed

Back to GalleryCategory Tags

Commercial FurnishingsProject Description

Flower Ring Completed

Back to GalleryCategory Tags

Commercial FurnishingsProject Description

Goode Co. - Bar stools

Back to GalleryYear Completed

2019Category Tags

Commercial FurnishingsProject Description

Goode Co. - Truss

Back to GalleryYear Completed

2019Category Tags

Commercial FurnishingsProject Description

Gold Table Base

Back to GalleryYear Completed

2021Cost for something similar

$3,080.00Project Description

Bronze Display table with sliding drawer

Back to GalleryYear Completed

2021Cost for something similar

$3,600.00Project Description

Houston Texans Tables

Back to GalleryYear Completed

2021Cost for something similar

1500.00Project Description

Bar height, round table top with custom logo created for the Houston Texans lounge bar at NRG stadium.

Hanging Bar Shelf with Wine Glass Racks

Back to GalleryYear Completed

2021Cost for something similar

$2,300Project Description

Steel constructed hanging bar shelf with built in wine glass holder on the bottom

Room Divider/ Privacy Screen

Back to GalleryYear Completed

2018Cost for something similar

$4,200Project Description

The Vine Chandelier

Back to GalleryYear Completed

2021Cost for something similar

3500.00Project Description

This one of a kind Chandelier was designed and fabricated for a vineyard tasting room in New Ulm, TX. It is constructed from steal and used wine barrels.

Bar Stool bases - SS

Back to GalleryYear Completed

2021Cost for something similar

2215.00 per stoolProject Description

Chandelier - State of Grace, 56 inch

Back to GalleryYear Completed

2015Cost for something similar

$6,500Project Description

Elegance in Brass and oyster. These chandeliers conceal their wiring so only the crisp lines, clean tubes, and smooth terminals support the frosted white shades. Everything that looks brass is brass. Steel and aluminum were cut and welded then powder coated oyster. This fixture is located at State of Grace Restaurant in Houston, TX.

Chandelier - Spring Cypress Presbyterian

Back to GalleryYear Completed

2015Cost for something similar

$4,000Project Description

A batch of six matching chandeliers were produced for Spring Cypress Presbyterian Church. They were remodeling their sanctuary and we were privileged to contribute.

The perimeters of the fixtures are cut with the church’s selected design. All parts are aluminum. Parts were water jet cut, slip rolled, welded, milled, and turned at HCMW and we handled the outside processing.

Room Divider - State of Grace Restaurant

Back to GalleryYear Completed

2015Category Tags

Commercial FurnishingsProject Description

Twenty four feet long and straight as an arrow. This divider has two continuous lengths of square tubing which fit through square holes milled in the vertical round tubes. This method maintained the straightness and consistency of the height. The glass panels are supported by water jet steel frames. The steel was sanded prior to welding and then cleaned and blackened. Brass accents cap the round tubes and provide fastening at the bases.

Light Fixtures - Steel and Brass, The State of Grace Restaurant

Back to GalleryYear Completed

2015Cost for something similar

$850 eachProject Description

A batch of nine light fixtures. The two layered backing plate is water jet from steel and the pieces welded with tubing between them. The plate has a pocket in the back which conceals the electrical box. All of the steel was cleaned and blackened. From the end of the brass tubing extends a chain with an assembled brass chandelier supporting six lights each. The power wire passes through the back plate, brass tube, is woven through the chain, and enters the hanging fixture. These fixtures are located at State of Grace Restaurant in Houston, TX.

Foot Rails - State of Grace Restaurant

Back to GalleryProject Description

These are the foot rails and stands at the main bar, chef’s kitchen bar, and oyster bar. The base was water jet from 1/4″ thick steel and TIG welded. Then the brass rings were brazed to to the stand. Once assembled the steel was blackened then the brass was cleaned. The tubes are blackened steel.

Oyster Bar - The State of Grace Restaurant

Back to GalleryYear Completed

2015Cost for something similar

Call for PricingCategory Tags

Commercial FurnishingsProject Description

The oyster bar at the State of Grace restaurant in River Oaks, Houston was made by HCMW. It took a combination of technology and hand working to produce this. The customer provided us with a digital design of the shape of the bar. Cutting that from a file would get us templates, but those templates needed trimming and fitting to match the actual structure in place. Once the templates were correct, we began to cut and hammer the brass over them. This is a time consuming process that is best not to be rushed. Like the main surface, the transaction counter was also hand hammered. Other trades trimmed out the main bar with a wooden elbow rest.

Liquor Cage - Hotel Galvez

Back to GalleryYear Completed

2013Category Tags

Commercial FurnishingsProject Description

The lobby bar of the Hotel Galvez is easily accessible after hours. Prior to construction of this cage, all of the alcohol had to be secured each night and returned to the bar each day. This cage is both attractive and functional. The panels have locks on the bottom that all share one key. Each panel weighs less than ten pounds and can be stored efficiently on a rack in the closet behind the bar. The dismantling of this cage takes less than five minutes each time. A great improvement over the time it takes to collect 75 bottles of liquor.

Nearby cabinet doors received matching cutout panels.

Exterior Cross - Spring Cypress Presbyterian Church

Back to GalleryYear Completed

2015Category Tags

Commercial FurnishingsProject Description

The church provided us with the artwork for their cross design. We water jet cut steel to match each piece of their cross, welded brackets to the back of them, and had them powder coated.

Road Dividers - Harrisburg Overpass

Back to GalleryYear Completed

2018Project Description

We produced 18 of these road dividers for Houston Metro. The magnolia design is cast into the concrete supports for the overpass as well.

Table Bases - Chef's Kitchen at The State of Grace Restaurant

Back to GalleryProject Description

All steel bases cut from plate steel and rectangular tubing. The steel was cleaned before and after welding and then blackened. One pair was made.

What should we build next?

Contact Us© Copyright 2024 Houston Custom Metal Works | Branding and website by Flywheel Co.