Gallery

The finished product

Our projects are artistic, mechanical, monochromatic, brightly colored, industrial, and visual. Simply put – they are as unique as our clients. The projects that allow us to bring your creation to life, is what we thrive on!

Range Hood - Stainless

Back to GalleryYear Completed

2018Cost for something similar

3600.00Project Description

Range Hood -Black Residential

Back to GalleryYear Completed

2020Cost for something similar

4500.00Project Description

Range Hood - Copper Commercial

Back to GalleryProject Description

Range Hood - Outside Kitchen

Back to GalleryYear Completed

2017Cost for something similar

4200.00Project Description

Signs - Friendswood Womans

Back to GalleryProject Description

This is a 3 part metal sign that is powder coated and layered on top of each other to create this unique 3 dimensional design, and hangs on a wall behind a receptionist desk. This particular design is roughly 3.5 feet tall and 1.5 feet wide.

Cabinet - Yellow

Back to GalleryYear Completed

2021Cost for something similar

$4,100Category Tags

Residential Furniture & CabinetryProject Description

Constructed from steel with adjustable feet, and powder coated to clients specific request

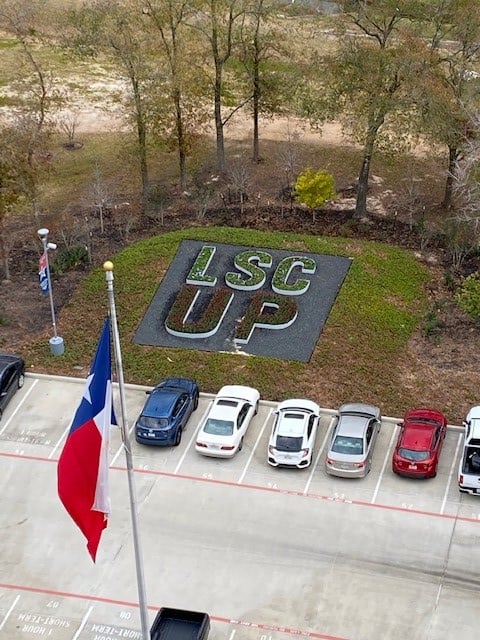

Planters - Lone Star College

Back to GalleryProject Description

These planters are located on the University Park Campus of Lone Star College and are constructed out of steal.

Escalantes - Hanging Bar Shelf & Wine Rack

Back to GalleryProject Description

Hye Rum Sign

Back to GalleryCategory Tags

SignsProject Description

HFD sign

Back to GalleryCategory Tags

SignsProject Description

Buffalo Bayou Park - Pause

Back to GalleryProject Description

Artist Anthony Thompson Shumate came to us to produce his project – Monumental Moments. These inspirational phrases are installed in Buffalo Bayou park in Houston, Texas. The four foot tall letters are cut from HDPE. What no one will ever see are the threaded stainless bars and galvanized tubing which lay under ground. This steel structure provides spacing and secure anchoring for the artwork.

Buffalo Bayou Park - Emerge

Back to GalleryProject Description

Artist Anthony Thompson Shumate came to us to produce his project – Monumental Moments. These inspirational phrases are installed in Buffalo Bayou park in Houston, Texas. The four foot tall letters are cut from HDPE. What no one will ever see are the threaded stainless bars and galvanized tubing which lay under ground. This steel structure provides spacing and secure anchoring for the artwork.

Fountain at Hotel Zaza

Back to GalleryProject Description

Fountain runnel designed and fabricated for the Memorial City Hotel Zaza. Constructed out of Stainless Steal

Durango Creek sign

Back to GalleryYear Completed

2014Category Tags

SignsProject Description

City of Hedwig Village - Rustic Sign

Back to GalleryProject Description

City of Hedwig Village - SS sign

Back to GalleryCategory Tags

SignsProject Description

City of Hedwig Village - City Hall Sign

Back to GalleryProject Description

OSP - Front

Back to GalleryProject Description

OSP - Back

Back to GalleryProject Description

HCMW - Sign

Back to GalleryCategory Tags

SignsProject Description

HCMW - Outside Sign

Back to GalleryCategory Tags

SignsProject Description

Flower Ring exposed

Back to GalleryCategory Tags

Commercial DécorProject Description

Flower Ring Completed

Back to GalleryCategory Tags

Commercial DécorProject Description

Brass counter top - Folkes

Back to GalleryYear Completed

2018Cost for something similar

$2,500Category Tags

Residential Furniture & CabinetryProject Description

Mirror Frames

Back to GalleryYear Completed

2018Cost for something similar

1200.00 for a pair. Mirror not includedCategory Tags

Residential Furniture & CabinetryProject Description

Fireplace Screen

Back to GalleryYear Completed

2018Cost for something similar

2000.00Category Tags

Residential Furniture & CabinetryProject Description

Range with handle

Back to GalleryProject Description

We had the pleasure of designing and fabricating this kitchen vent hood for one of our clients.

Goode Co. - Bar stools

Back to GalleryYear Completed

2019Category Tags

Commercial DécorProject Description

Goode Co. - Truss

Back to GalleryYear Completed

2019Category Tags

Commercial DécorProject Description

Gold Table Base

Back to GalleryYear Completed

2021Cost for something similar

$3,080.00Project Description

Bronze Display table with sliding drawer

Back to GalleryYear Completed

2021Cost for something similar

$3,600.00Project Description

Custom logo sign - Skunk

Back to GalleryProject Description

Garden Trellis

Back to GalleryYear Completed

2021Cost for something similar

$2,600Category Tags

Residential Furniture & CabinetryProject Description

Vine support

Back to GalleryYear Completed

2021Cost for something similar

$1,700Category Tags

Residential Furniture & CabinetryProject Description

Houston Texans Tables

Back to GalleryYear Completed

2021Cost for something similar

1500.00Project Description

Bar height, round table top with custom logo created for the Houston Texans lounge bar at NRG stadium.

Hanging Bar Shelf with Wine Glass Racks

Back to GalleryYear Completed

2021Cost for something similar

$2,300Project Description

Steel constructed hanging bar shelf with built in wine glass holder on the bottom

Lounge Chairs

Back to GalleryYear Completed

2021Cost for something similar

$4200.00 for the pairCategory Tags

Residential Furniture & CabinetryProject Description

Made from square tube steel, and finished with a beautiful textured fabric and leather strapping arm rest

Kitchen Island

Back to GalleryYear Completed

2017Cost for something similar

$11,060Category Tags

Residential Furniture & CabinetryProject Description

Room Divider/ Privacy Screen

Back to GalleryYear Completed

2018Cost for something similar

$4,200Project Description

Brass and Stainless Range Hood - 1

Back to GalleryProject Description

Brass and Stainless Range Hood - 2

Back to GalleryProject Description

The Vine Chandelier

Back to GalleryProject Description

This one of a kind Chandelier was designed and fabricated for a vineyard tasting room in New Ulm, TX. It is constructed from steal and used wine barrels.

Bar Stool bases - SS

Back to GalleryYear Completed

2021Cost for something similar

2215.00 per stoolProject Description

Chandelier - State of Grace, 56 inch

Back to GalleryProject Description

Elegance in Brass and oyster. These chandeliers conceal their wiring so only the crisp lines, clean tubes, and smooth terminals support the frosted white shades. Everything that looks brass is brass. Steel and aluminum were cut and welded then powder coated oyster. This fixture is located at State of Grace Restaurant in Houston, TX.

Chandelier - Spring Cypress Presbyterian

Back to GalleryProject Description

A batch of six matching chandeliers were produced for Spring Cypress Presbyterian Church. They were remodeling their sanctuary and we were privileged to contribute.

The perimeters of the fixtures are cut with the church’s selected design. All parts are aluminum. Parts were water jet cut, slip rolled, welded, milled, and turned at HCMW and we handled the outside processing.

Room Divider - State of Grace Restaurant

Back to GalleryYear Completed

2015Category Tags

Commercial DécorProject Description

Twenty four feet long and straight as an arrow. This divider has two continuous lengths of square tubing which fit through square holes milled in the vertical round tubes. This method maintained the straightness and consistency of the height. The glass panels are supported by water jet steel frames. The steel was sanded prior to welding and then cleaned and blackened. Brass accents cap the round tubes and provide fastening at the bases.

Chandelier - Frame Umbrella, 34 inch

Back to GalleryYear Completed

2016Cost for something similar

$3,500Project Description

This all aluminum framework chandelier has an umbrella profile with six perimeter light extensions and one central light extension. On this example the shades were chosen to match the main kitchen chandelier. The six perimeter shades are smaller in size and the one central shade is larger than the other six. The aluminum terminals, tubes, and main wiring bowl were anodized to match the kitchen hardware and the body was powder coated to match the cabinet paint.

Light Fixtures - Steel and Brass, The State of Grace Restaurant

Back to GalleryYear Completed

2015Cost for something similar

$850 eachProject Description

A batch of nine light fixtures. The two layered backing plate is water jet from steel and the pieces welded with tubing between them. The plate has a pocket in the back which conceals the electrical box. All of the steel was cleaned and blackened. From the end of the brass tubing extends a chain with an assembled brass chandelier supporting six lights each. The power wire passes through the back plate, brass tube, is woven through the chain, and enters the hanging fixture. These fixtures are located at State of Grace Restaurant in Houston, TX.

Brass Counter - Private Home

Back to GalleryYear Completed

2016Cost for something similar

$2,800Category Tags

Residential Furniture & CabinetryProject Description

This counter surface is yellow brass. The edge was formed by hand hammering. Subtle distressing and hammer marks are visible on the front face. The surface was left un-coated so that with time it will age, and with aggressive cleaning it can be lightened.

Foot Rails - State of Grace Restaurant

Back to GalleryProject Description

These are the foot rails and stands at the main bar, chef’s kitchen bar, and oyster bar. The base was water jet from 1/4″ thick steel and TIG welded. Then the brass rings were brazed to to the stand. Once assembled the steel was blackened then the brass was cleaned. The tubes are blackened steel.

Oyster Bar - The State of Grace Restaurant

Back to GalleryProject Description

The oyster bar at the State of Grace restaurant in River Oaks, Houston was made by HCMW. It took a combination of technology and hand working to produce this. The customer provided us with a digital design of the shape of the bar. Cutting that from a file would get us templates, but those templates needed trimming and fitting to match the actual structure in place. Once the templates were correct, we began to cut and hammer the brass over them. This is a time consuming process that is best not to be rushed. Like the main surface, the transaction counter was also hand hammered. Other trades trimmed out the main bar with a wooden elbow rest.

Custom Stair Case

Back to GalleryYear Completed

2018Cost for something similar

$50,000.00Category Tags

Residential Furniture & CabinetryProject Description

Custom Staircase railing that was hand bent and each piece set in place.

Liquor Cage - Hotel Galvez

Back to GalleryYear Completed

2013Category Tags

Commercial DécorProject Description

The lobby bar of the Hotel Galvez is easily accessible after hours. Prior to construction of this cage, all of the alcohol had to be secured each night and returned to the bar each day. This cage is both attractive and functional. The panels have locks on the bottom that all share one key. Each panel weighs less than ten pounds and can be stored efficiently on a rack in the closet behind the bar. The dismantling of this cage takes less than five minutes each time. A great improvement over the time it takes to collect 75 bottles of liquor.

Nearby cabinet doors received matching cutout panels.

Kitchen Island - blackened steel

Back to GalleryYear Completed

2017Cost for something similar

10,000Category Tags

Residential Furniture & CabinetryProject Description

This eight foot long island base features blackened steel panels, tube steel frame and exposed rivets. The back side as an eight inch deep storage area for hanging pans behind the four matching doors. The front side has pockets for an ice machine and a dish washer.

Steel Side Board

Back to GalleryYear Completed

2018Cost for something similar

3,000Category Tags

Residential Furniture & CabinetryProject Description

Tube steel construction with Spanish pattern doors cut on site. The central cabinet is separated from the side shelves with carbon steel sheets. Built to match the space.

Steel kitchen cabinet

Back to GalleryYear Completed

2018Cost for something similar

8,000Category Tags

Residential Furniture & CabinetryProject Description

All steel kitchen cabinet with frosted glass accents. All welds ground and panels clear coated after production. Multiple sizes of spice shelves span the full height of the doors. The main interior shelves are galvanized steel and adjustable in height. The hidden feet are adjustable for leveling

Steel range hood

Back to GalleryYear Completed

2017Cost for something similar

4400.00Project Description

All steel construction for residential vent hood. The materials match cabinets and shelves we made for the rest of this home.

Kitchen island decoration

Back to GalleryYear Completed

2018Cost for something similar

5,000Category Tags

Residential Furniture & CabinetryProject Description

Stainless steel decoration for the front of a kitchen island. Mill finish stainless steel tubes over sanded stainless steel sheet. The customer’s carpenter delivered the raw wood island piece to us and we applied our metalwork to the front side then returned it to the site for the carpenter to finish the piece.

Anchor Doors

Back to GalleryYear Completed

2013Category Tags

Public ArtProject Description

The anchor design on the doors and the steel tube frames were provided by artist Gary Sweeney. In order to weld them into their spaces and not have unsightly gaps each panel needed to fit snugly. All three doors were meticulously measured and individual panels were cut which conform to the subtly unique dimensions of each space. Once welded the doors were sent out for powder coating. The last step was attaching the perforated stainless steel screens to the back side of the designs.

Bicycle Racks - East End

Back to GalleryYear Completed

2013Category Tags

Public ArtProject Description

Anthony Thompson Shumate of ACTS Studios designed the bicycle racks for the Greater East End Management District. HCMW cut them from 7/8 inch thick plate steel and had them hot dip galvanized. Some were cut with extensions that are sunk into the concrete pad they sit on. Some have feet welded to the bottom of them and they are bolted on top of their concrete pads.

Road Dividers - East End Navigation Boulevard

Back to GalleryProject Description

Artist Gary Sweeney provided the artwork and design for 28 road dividers. We cut and welded the square tube steel frames around water jet artwork. The finished weldments were powder coated. Installation was handled by the Greater East End Management District. Five of them are unique designs and are eleven feet long. The remaining 23 are four designs repeated which are each seven feet long.

Monumental Moments – Verbs

Back to GalleryProject Description

Artist Anthony Thompson Shumate came to us to produce his project – Monumental Moments. These inspirational phrases are installed in Buffalo Bayou park in Houston, Texas. The four foot tall letters are cut from HDPE. What no one will ever see are the threaded stainless bars and galvanized tubing which lay under ground. This steel structure provides spacing and secure anchoring for the artwork.

Gateways at the Esplanade on Navigation

Back to GalleryProject Description

These decorative archways were designed by artist Gary Sweeney and produced by HCMW. They delineate the two ends of the Esplanade at Navigation Boulevard in Houston. Each is all steel and roughly 15 feet tall and 15 feet wide. The artwork was provided to HCMW and then cut out of three sheets of steel which when laid next to each other fit seamlessly. The sheets were welded at the joints and then welded to a 2″ square tube frame. The entire assembly was powder coated prior to delivery. Installation was handled by the on site contractors.

Exterior Cross - Spring Cypress Presbyterian Church

Back to GalleryYear Completed

2015Category Tags

Commercial DécorProject Description

The church provided us with the artwork for their cross design. We water jet cut steel to match each piece of their cross, welded brackets to the back of them, and had them powder coated.

Road Dividers - Harrisburg Overpass

Back to GalleryYear Completed

2018Project Description

We produced 18 of these road dividers for Houston Metro. The magnolia design is cast into the concrete supports for the overpass as well.

Brass Kitchen Counters at the BOHO Cottage in Vintage Round Top

Back to GalleryYear Completed

2017Cost for something similar

$6,000Category Tags

Residential Furniture & CabinetryProject Description

Custom brass counter tops were added to the kitchen design of the BOHO Cottage at the world famous Vintage Round Top. Also featured on Emily Henderson’s Interior Design Blog of HGTV. Photography by Tessa Neustadt.

Table - Brass Flower in Concrete, Aluminum Legs

Back to GalleryProject Description

The smooth concrete top is embellished with a brass flower. The legs are water jet from 3/8 inch thick aluminum and welded to the top support. The base is powder coated teal.

Table - Console A.1

Back to GalleryProject Description

This table mimics elegant console tables more commonly made from wood. The contours are inspired by Victorian designs; most noticeably in the legs. The table is all aluminum. Prior to welding each piece is sanded to produce a shiny metallic surface. After welding the whole table was powder coated clear to show off the natural color. The designs in the top are cut all the way through the Aluminum.

This design can be powder coated solid colors as well.

Table - Austin Co Slice ET

Back to GalleryCost for something similar

$450Category Tags

Residential Furniture & CabinetryProject Description

Wooden top harvested from drought killed oak in Austin County. The base is sanded and clear coated steel. Modern design.

Stainless Steel Tube table base

Back to GalleryYear Completed

2017Cost for something similar

1,800Category Tags

Residential Furniture & CabinetryProject Description

Table base made from stainless steel. The tubes were rolled and the plate water jet in house before TIG welding. Sanded finish on all pieces.

Table - QTTS

Back to GalleryCost for something similar

$7,000Category Tags

Residential Furniture & CabinetryProject Description

Quick Trick Tube Stack. This table uses something as strong as pipe in a non-traditional manner and then gives it an industrial finish for artistic sake. The pipes are cut and welded to a steel back bone and the pieces are then hot dip galvanized. The zinc coating is not uniform in color or pattern.

Table - Pipe Moons

Back to GalleryCost for something similar

$5000Category Tags

Residential Furniture & CabinetryProject Description

This conference sized table is both artistic and industrial. Steel pipe provides strength and subtle arcs show elegance. Minimizing the supports leaves clear space. Within the framework.

Table Bases - Chef's Kitchen at The State of Grace Restaurant

Back to GalleryProject Description

All steel bases cut from plate steel and rectangular tubing. The steel was cleaned before and after welding and then blackened. One pair was made.

Table Bases - Pineapple, End Table Height

Back to GalleryYear Completed

2017Cost for something similar

$315 eachCategory Tags

Residential Furniture & CabinetryProject Description

This pair of bases stand 23 inches tall. The design is cut from steel and fanned out to reveal the shape of a pineapple. The steel was sand blasted and clear powder coated. Direct light shows a subtle metallic sparkle.

These can be powder coated most colors.

Table - Picture Frame

Back to GalleryCost for something similar

$750Category Tags

Residential Furniture & CabinetryProject Description

Cascading layers of aluminum form the top of this drinks ready coffee table. The lower ring emulate the clover shaped top. Powder coated satin black the top has a painted gold middle ring.

20″ tall x 36″ wide x 18″ deep.

Steering Levers

Back to GalleryCategory Tags

IndustrialProject Description

These assemblies incorporate all major activities at HCMW; 3D design, Milling, Turning, and Water Jet cutting. These are made from stainless steel and aluminum. The teak handle is turned in house. We facilitate the outside processing. We acquire the hardware. We assemble the parts and provide the finished product in a box that goes on the customer’s shelf until it is taken out to the field and installed.

Tortilla Machine

Back to GalleryProject Description

This machine was first fully realized in 3D. Once the design was evaluated and approved, production of the Make parts began. This included water jetting plate, CNC milling, CNC turning, forming, and sending some parts for outside processing. All hardware was ordered and coordination with the customer for a few unique parts he was supplying. Assembly of all mechanical components was completed and the machine was picked up by the customer. It is currently out for UL and FDA testing.

Table - Deep Sea Hose Display

Back to GalleryProject Description

This table was built to display a deep sea hose at OTC. The customer’s name and parent company logo are cut into the base. It is made from 1/2″ thick steel and fully welded at all joints. Originally the customer wanted a plain, square tube steel table. I designed this and presented it as a more artistic option.

Hose Skiver

Back to GalleryYear Completed

2014Category Tags

IndustrialProject Description

The customer needed a tool to peel multi layer, deep sea hose like an apple peeler would. This tool clamps onto a mandrel placed in the end of the tube and slices off varying depths of rubber to expose steel braided wires. HCMW generated the 3D design before any metal was cut. Water jetting, CNC milling, CNC turning, and welding were all necessary. The threading for the two main bodies is a non-standard acme thread similar to others used by the customer.

What should we build next?

Contact Us© Copyright 2024 Houston Custom Metal Works | Branding and website by Flywheel Co.